Rigaku

NEX OL - Process Elemental Analyzer

PRODUCT OVERVIEW

On-line, real-time analysis by Energy Dispersive X-ray Fluorescence (ED XRF)

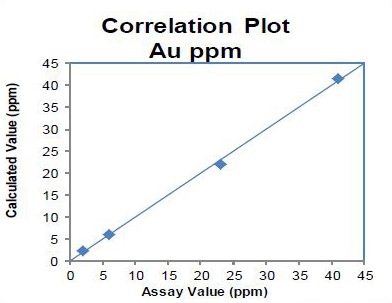

The Rigaku NEX-OL series of On-line EDXRF analysers incorporate the new array of XRF Tube and detector. Built specifically for on-line liquid and film/sheet material analysis, the elemental coverage is from Aluminium to Uranium. Multi element analysis is available for example metallurgical suites such as Gold and Silver, Platinum/Palladium.

The on-line system has been designed for industrial conditions with tool-less quick replacement of the optic window and processor protection from pipeline pressure pulsations. With special custom designed cabinets the system can be used in classified and non-classified zones of a process operation.

The Rigaku On-line XRF analyser has been applied to monitoring the QC on film and continuous sheet production. With surface treatments such as silicone coating or cleaning foil surfaces, the XRF analysis can be used to determine the coating thickness or the presence of chemical contamination.

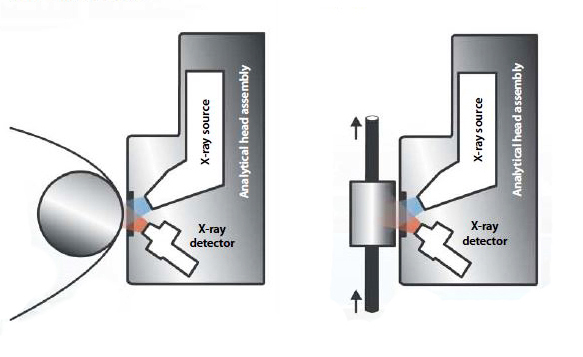

Special flow cell assembly for fluids to ensure constant pressure.

KEY FEATURES

- Real-time process control by elemental analysis

- Measure simultaneous multi elements (₁₃Al to ₉₂U)

- From ppm levels to weight percent (wt%)

- Robust NEX QC⁺ optics with SDD detector

- Industrial touch screen user interface

- Easy empirical calibration and routine operation

- Toolless routine maintenance of analytical head

- Multiple remote analysis heads (non-classified)

- Liquid flow cell leak sensor

- No dangerous radioisotopes

MEASURES

Fast simultaneous multi element analysis using SDD detector.

Two standard measurement cells for liquid flow or continuos foil/sheet material.

Applications include:

- Gold leaching processing

- Monitoring chemical bath solutions - Ni, Co,Mo,Zn, In

- Refinery Products - S, Cl

- Packaging - Si

- Food Processing - Cl

SPECIFICATIONS

Go back to ED XRF Spectrometers

Go back to ED XRF Spectrometers